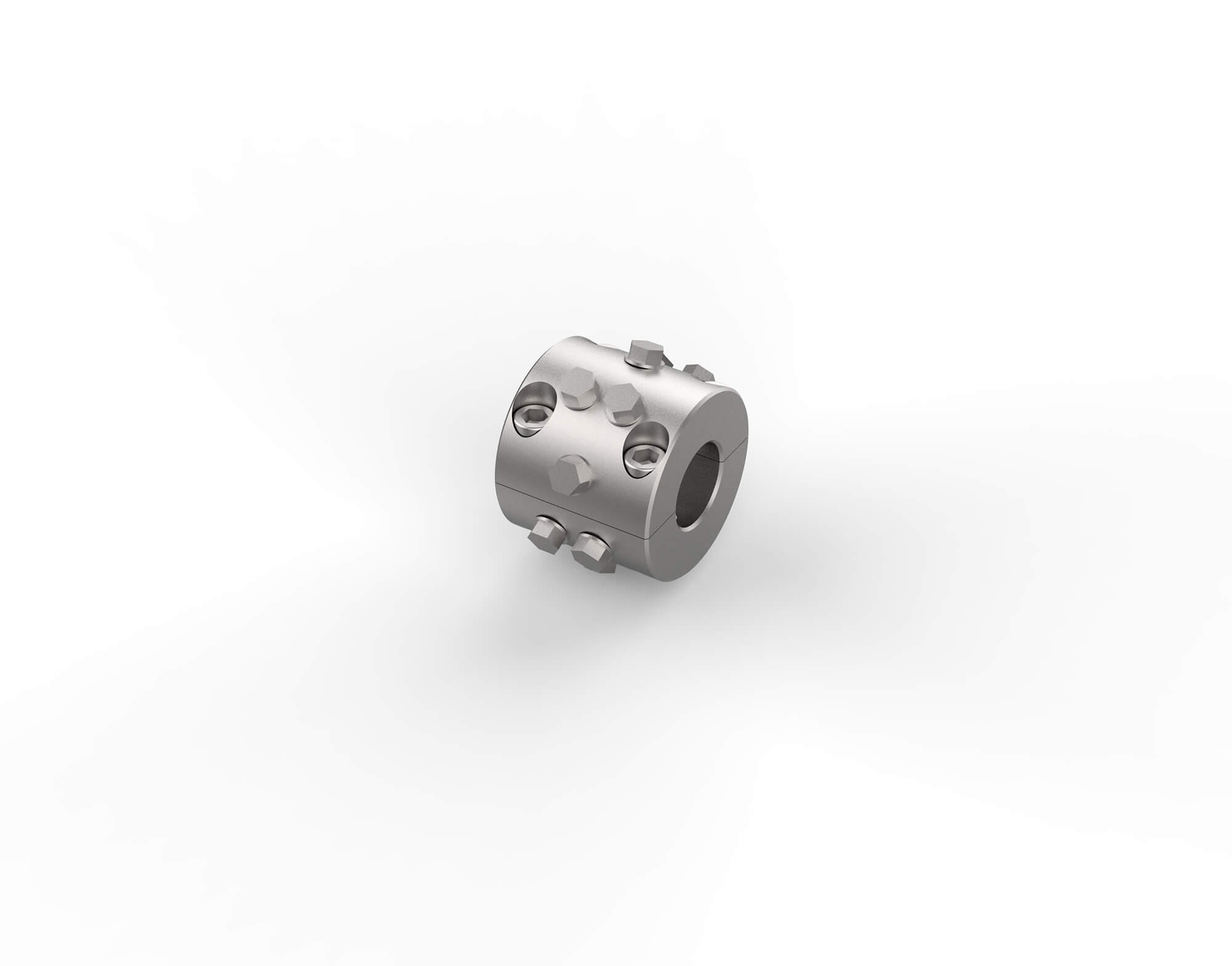

Manual Dimple Jig Assembly

The WellEnTech Manual Dimple Jig Assembly provides a means of manually dimpling coiled tubing onto a Dimple-on Coil Connector*. This cost effective jig enables the dimpling process to be carried out without the need for a hydraulic pump or hefty yolk arrangement.

Description

Features

- Compact design

- Standard hex head sizes

- Compatible for a range of coil wall thicknesses

Applications

- For dimpling coiled tubing onto Dimple-on Coil Connectors*

- Suitable for all grades of coiled tubing

* Dimple-on Coil Connectors, Pressure Test Subs, Pull Test Subs and CT Reamer Assemblies are all available from Wellentech.

Operation

The WellEnTech Manual Dimple Jig Assembly consists of two halves which are bolted together. There are two grub screws, one for orientation on the Connector and one for securing the jig onto the Coiled Tubing. Each of the Dimple Screws are then tightened to a specific torque value, which results in the forming of dimples onto the Dimple-on Coil Connector. A pull test will confirm the connector has been fitted correctly and a pressure test will verify that a seal has been maintained. It is recommended that the Coiled Tubing is prepared with a WellEnTech CT Reamer Assembly* prior to installing the Connector.