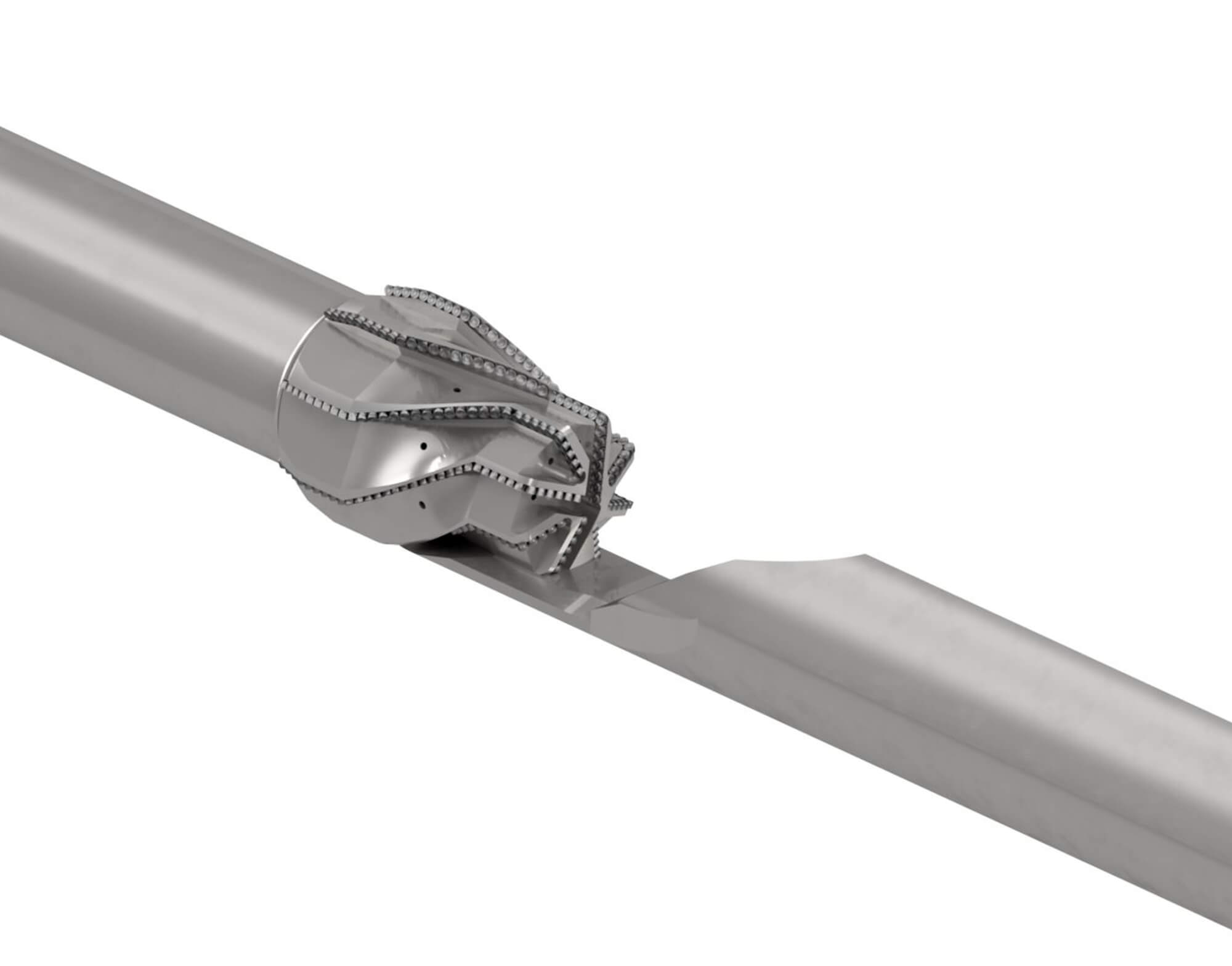

WellEnTech™ ST Casing Exit System

TheWellEnTechST™ Casing Exit System is a Single Trip System that can be hydraulically or mechanically set. The design utilises tried and tested technology while incorporating some new design features for easy whip to mill hook up and reduce the amount of additional components to be milled without compromising on functionality or strength. TheMill Head and Ramp are designed to complement each other for flexibility, ease of shear out, mill starting and centre point elimination.This design delivers a smooth exit and beyond into the new well bore.The system enables 360 degree exit capability making it an ideal solution to a variety of casing exit scenarios.

Description

Features

- Single Trip Design

- Fully Retrievable

- Tried and tested Knock off plug design

- No internal Burst Disc required

- Retrieval Hook slot in whip face

- Suitable for Hydraulic or Mechanical Setting

- High torsional and tensile yield

- Easy to assemble and redress

Applications

- Sidetracks

- Multilaterals

Operation

The WellEnTech Casing Exit System is easily assembled with the use of basic tools. Packer hookup at hinge point &mill head hook up to ramp are all designed for ease and safety.

Casing Exit system is run in hole to setting depth where the Whipstock is oriented using MWD or Gyroscope.With the mill head ports isolated, the Anchor is set hydraulically via the setting port. Once anchor is set and the mill sheared out, rotation of the mill will establish full flow through the mill when it contacts the whip tip. It is advisable to run a WellEnTech Running Tool with the system to ensure clean hydraulic fluid is used to set the Packer or Anchor.

Mill is shear released from the ramp (shear can be up only or bi directional as required) to enable milling of the casing exit and 10-15ft of rat hole. The result is a full gauge easily accessible window with minimal milling time.