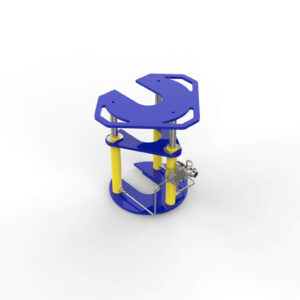

External Dimple Jig Assembly

The WellEnTech External Dimple Jig Assembly provides a means of dimpling Coiled Tubing prior to fitting External Dimple Connectors, which are also available from WellEnTech (Ref Data Sheet DS-085). The External Dimple Jig Assembly consists of a Dimple Sub, for dimpling the Coiled Tubing, a slide Hammer for knocking the Assembly on and off of the tubing and a Removal Sub for attaching to the Connector during its removal. Each Jig is designed to suit a specific diameter of Coiled Tubing and will dimple a range of wall thicknesses. The Removal Subs are furnished with a range of threaded connections

Description

Features

- Compact design

- Standard hex head sizes

- Compatible for a range of coil wall thicknesses

Applications

- For dimpling coiled tubing to suit External Dimple Connectors*

- Suitable for all grades of coiled tubing

* External Dimple Connectors, Pressure Test Subs and Pull Test Subs are all available from WellEnTech.

Operation

The WellEnTech External Dimple Jig Assembly consists of two three distinct components, the Dimple Sub, the Hammer and the Removal Sub. The Dimple Sub creates the Dimples on the Coiled Tubing, this is achieved by tightening hardened Dimple Screws which produce a uniform dimple of the exact size to suit the External Dimple Connector. The Hammer is used to knock on and off the Dimple Sub, Knock on the External Dimple Connector or also remove the Connector. The Removal Sub provided a means of holding onto the Connector during fitting and removal. A pull test will confirm the External Dimple Connector has been fitted correctly and a pressure test will verify that a seal has been maintained.